Description

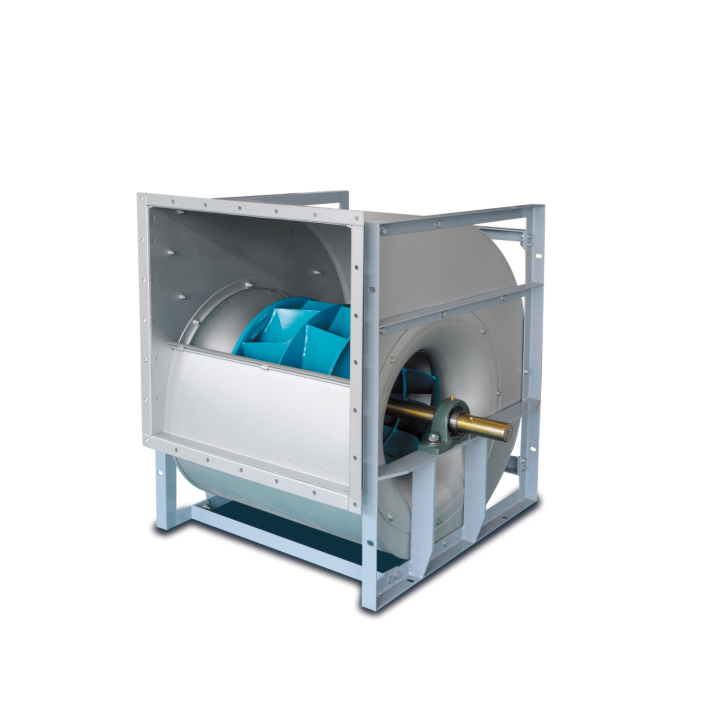

Housing For all sizes except 1250 and above, the housing is manufactured in galvanized sheet steel with the housing fixed to the side plates in "the Pittsbourgh seam method" form system. Housings for 1250 and 2000 are manufactured in mild steel finished with polyester powder coating finish. Fully welded steel plate housings with painted finish are available for all size upon request.

The impeller is made of cold rolled sheet steel backward curved blades with polyester powder coating finish. The impeller is secured to the shaft through a steel or aluminum hub. Hub bore is precision machined and incorporates a keyway and locking screw.

The fan must be stabilised on a base (frame or platform) to ensure no structural deformations caused by the tension of the belts. This will increase the life time of the fan. The frame is manufactured with galvanized angular bars for type "C". some type are manufactured with sections of steel with polyester powder coating finish.

Shafts are manufactured from C45 carbon steel using an automatic process for positioning and cutting of the keyways. All dimensional tolerances of the shaft are fully checked to ensure a precise fit. All shafts are then coated with an anti-corrosion varnish after assembly.

Bearings used are either deep groove ball bearing with an adaptor sleeve or spherical roller bearings sealed at both sides for different duty application.

Features

■ Optimally engineered for HVAC applications.

■ High quality, compact design.

■ High efficiency, low power consumption.

■ Quiet operation.

■ Performance and Noise data according to DIN 24166,accuracy Class 1.

■ Standard operating temperature between -20°C and +60°C.