-

E1041 and E1061 display

The E1041 and E1061 operator panel is developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text, dynamic

indication, time channels, alarm and recipe handling are included.

-

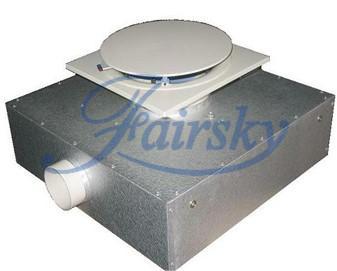

Cabin Unit

Cabin Unit is the terminal device of the air conditioning system, which are applicable for the lodging cabins, dining halls, offices, meeting rooms and so on in the vessels, which can also be used as the terminal device of the hotels, hospitals, large meeting halls, etc.

-

Retrofit & upgrade service

We can offer many aspects of refrigeration services. We have a team of refrigeration engineers in many ports around the china and can arrange for a fully-qualified engineer to attend vessels in many locations. Our vast experience includes trouble-shooting and problem-solving, as well as full plant conversions to new refrigerants. We can also provide annual inspection agreements to ensure that breakdowns and failures are kept to a minimum and systems are well maintained. We can provide customers with “7*24″ mode support.

-

R22 and R404a Phase out

Several refrigerants are available as replacement for R22 and R404A. Some of these refrigerants are known as “direct replacement or drop in refrigerants”, and can in theory replace R22 and R404A without any modifications to the original installation.

-

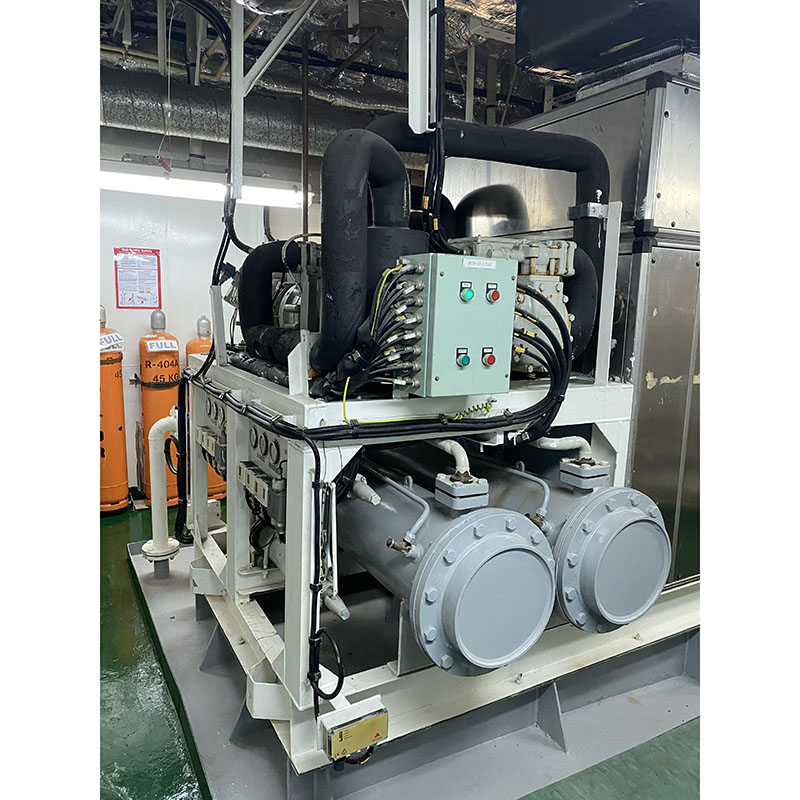

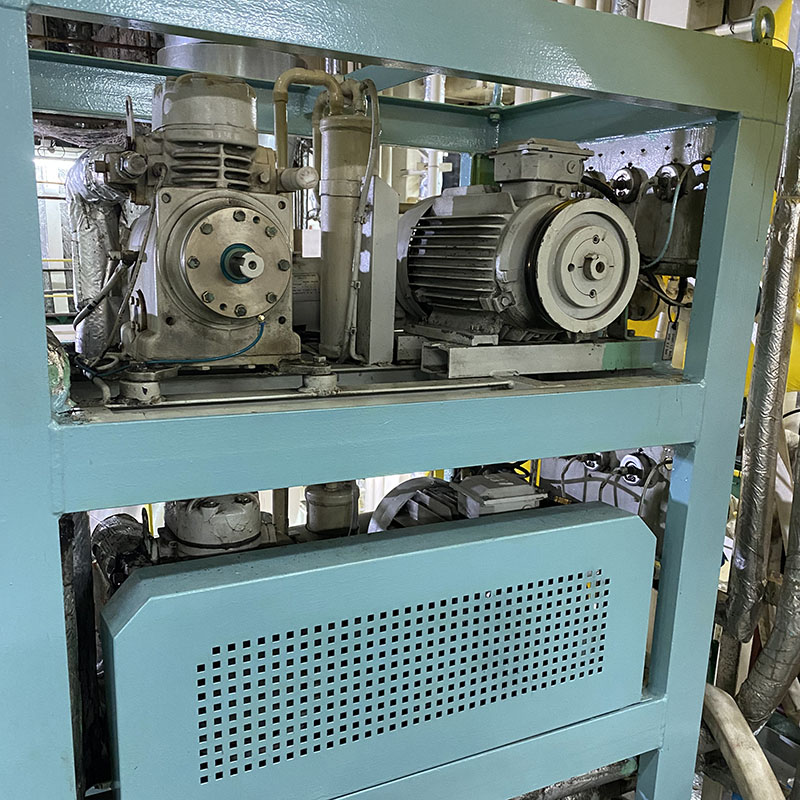

Overhaul and repair

We have a team of refrigeration engineers in many ports around the china and can arrange for a fully-qualified engineer to attend vessels in many locations. Our vast experience includes trouble-shooting and problem-solving. We can provide customers with “7*24*365″ mode support.

-

Mantenance

We can provide a carefully planned maintenance schedule of safety inspections and technical check-ups at 6 or 12-month intervals, and maintenance checks or overhauls at intervals of 2–4 years. These inspections and overhauls extend the working life of the system and help prevent expensive and unnecessary operational breakdowns. Whenever possible, they are scheduled to coincide with a ship’s docking, or other major work aboard.

-

Leakage test and Repair

The leakage in the refrigeration system is a common fault in the operation of air-conditioning refrigeration equipment. Once it occurs, it will not only affect the normal use of the equipment, but also cause serious failure of the compressor.

-

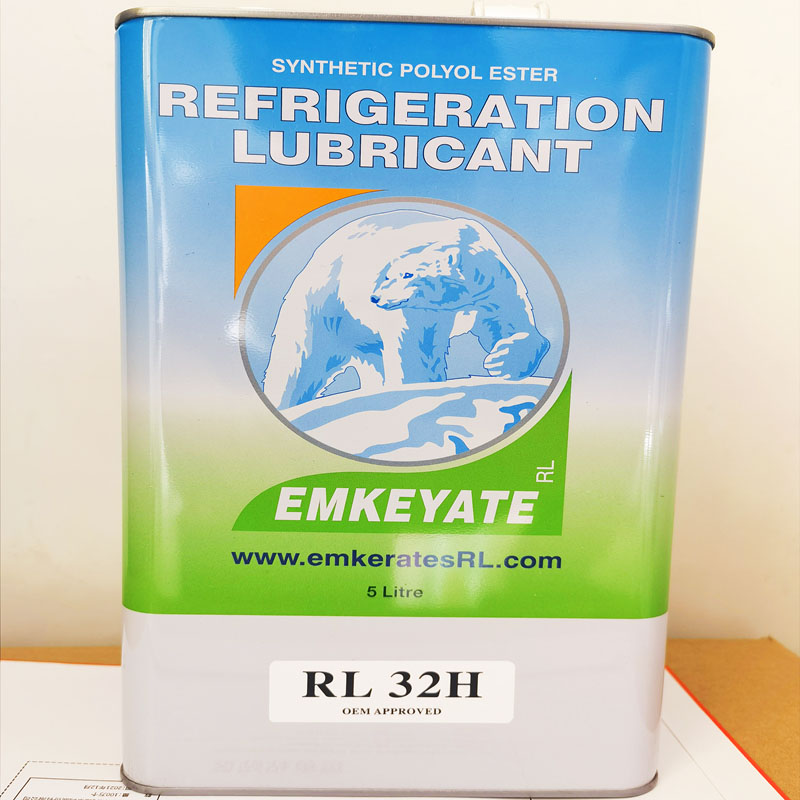

Lub. oil

The polyol ester (POE) lubricants are designed to meet the needs of a wide range of compressor types in systems using HFC refrigerants.

-

Compact and horizontal type Sea water Cooled Condenser

Heat exchanger also called heat transfer machine, is the equipment that can transfer certain heat from the thermal fluid to the cold fluid. It is the essential equipment to achieve the heat exchange and transfer during the production process. It’s the evaporator that the cold water flows in the tube and the refrigerant evaporates in the shell. It’s one of the main styles of refrigerating unit that cool the secondary refrigerant. It commonly adopt horizontal type, which has the characteristic of effective heat transfer, compact structure, small occupied area and easy installation etc.

-

Horizontal and vertical liquid receivers

The function of the liquid receiver is to store the liquid refrigerant supplied to the evaporator. After the high-pressure refrigerant passes through the heat dissipation effect of the condenser, it becomes a gas-liquid two-phase state, but the refrigerant must enter the evaporator in a liquid state. Good cooling effect, so a liquid receiver must be installed behind the condenser to store the high-pressure refrigerant here, and then the liquid refrigerant drawn from the bottom is sent to the evaporator, so that the evaporator can play its best state. Achieve the best cooling effect.

-

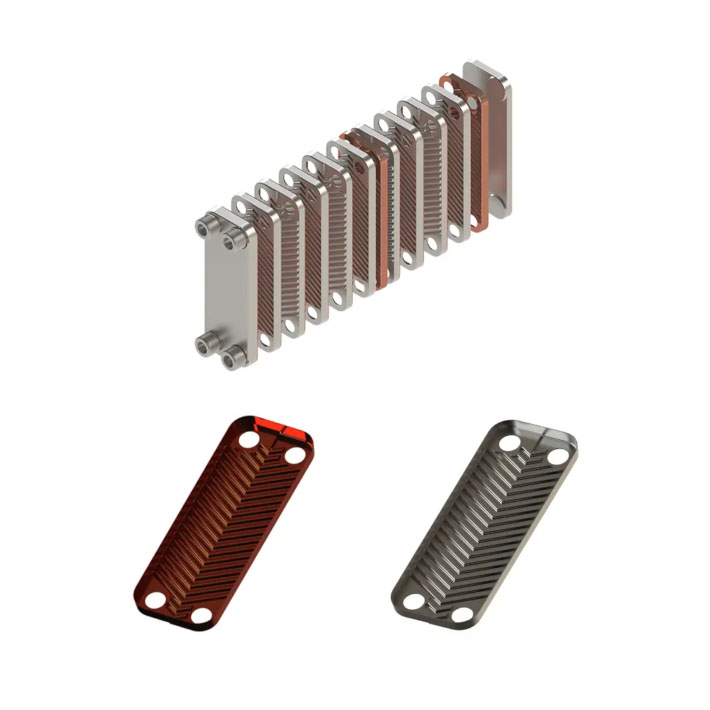

High-efficiency and compact Brazed Plate Heat Exchanger

Brazed plate heat exchanger is a kind of partition heat exchanger. It is a new type of high-efficiency heat exchanger made by stacking a series of metal sheets with a certain corrugated shape and brazing in a vacuum furnace. Thin rectangular channels are formed between various plates, and heat exchange is carried out through the plates.

-

Copper tubes with aluminum Heating coils

The heating coils are made from a series of copper tubes with aluminum or copper fins to increase the heat transfer surface areas. Either a heating fluid is circulated through the tubes whilst a hot air stream passes over the tubes and fins. The heating coils for the hot water or steam housed in a sheet steel frame. The steam is supplied and discharged through headers with connections extended through the access side of the air handling unit.

- sales@fairskycn.com

- 0086-13817905636