Description

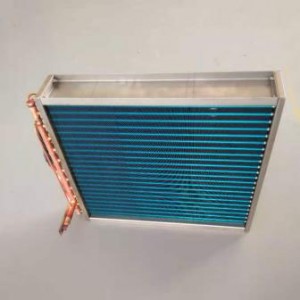

The Heating Coils help power the broadest line of air handling equipment in the industry – equipment that relies on these coils for a comfortable indoor temperature control. With high quality performance and a broad selection of loose coils for use with water or steam, our hot and chilled water coils are available in multiple diameters and different types of material.

The heating coils must be kept clean of dust and foreign matters with a view to the heating efficiency. Cleaning is effected by means of vacuum cleaning at the air inlet and, in special cases, by means of compressed air from the air outlet. Cleaning must be performed cautiously, as the aluminum fins are vulnerable to damage. If the filters of the unit are maintained according to the instructions, the cleaning interval will be every 3rd year, but more frequent examination is recommended.

The components of the pipe system for regulation and ventilation as well as other components essential for the operation of the heating coils must be maintained in accordance with the instructions and their proper function must be checked at regular intervals.

If during repair of the heating coils, it proves necessary to disassemble and later assemble pipe connections, the headers with threaded connections must be retained to avoid distortion and leakage of the copper tubes of the heating coils.

Features

1. Good sealing performance.

2. Elimination of leakage.

3. High heat exchange efficiency.

4. Easy maintenance.